- About ERA

-

Products

- Valve

-

Pressure

- PVC Pressure Pipes Fittings PN10 (ISO1452)

- PVC Pipes Fittings TYPE II

- PVC Pressure Pipes Fittings PN16(DIN8063)

- PVC Pipes Thread Fittings BS Standard

- PVC SCH40 Pipes & Fittings (ASTM D2466)

- PVC SCH40 Pressure Fittings Type II

- PVC SCH80 Pipes & Fittings (ASTM D2467)

- PVC Pressure Fittings(BS4346)

- PVC Pressure Fittings JIS Standard

- PVC Pressure Pipes & Fittings(AS/NZS1477)

- PVC Pressure Pipes with Gasket

- PP Compression Fittings Valves & Filters(ENIS01587AS/NZS4129)

- II PP Compression Fittings

- PE Butt Weilding & Socket Welding Fittings

- Pressure for Hot and Cold

- Rain Gutter

- Drainage

- Fire Protection

- Electric Fusion

- Electric Conduits and Fittings

- Electric Switch

- Accessories

-

Applications

-

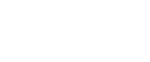

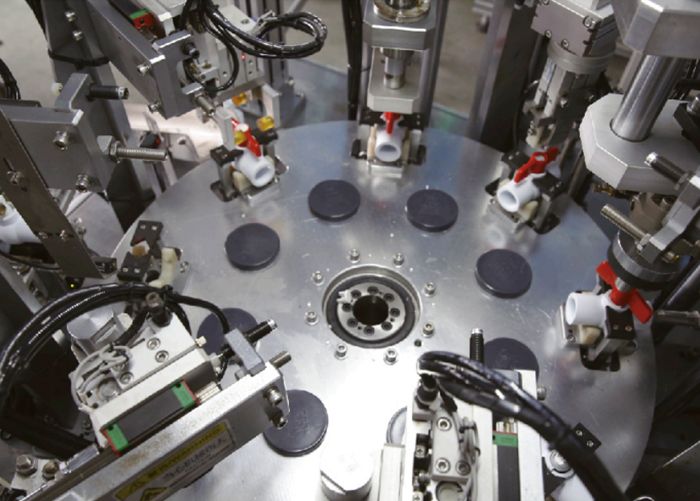

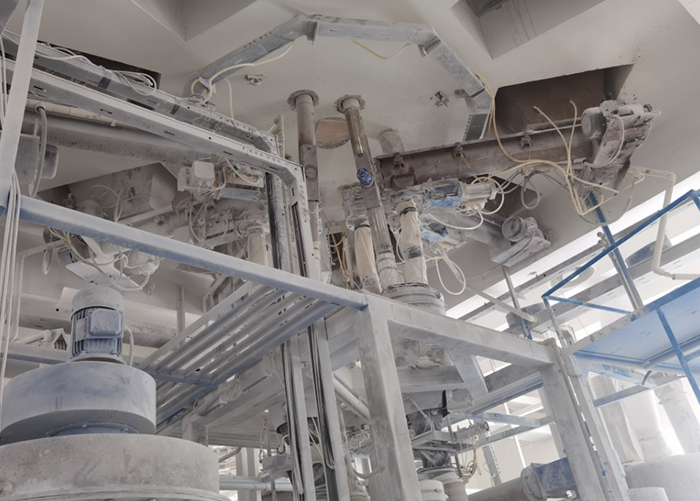

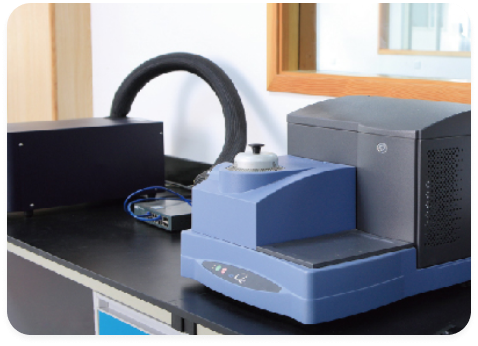

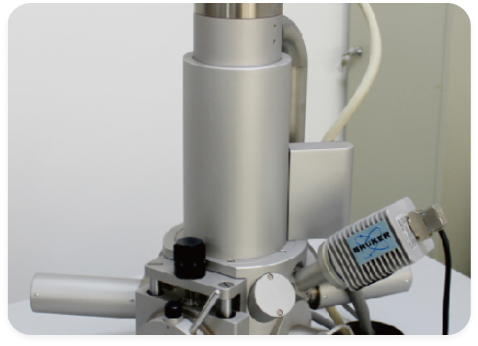

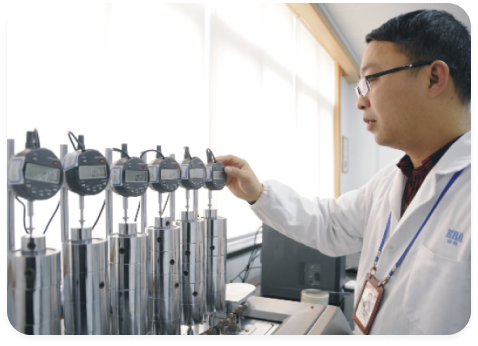

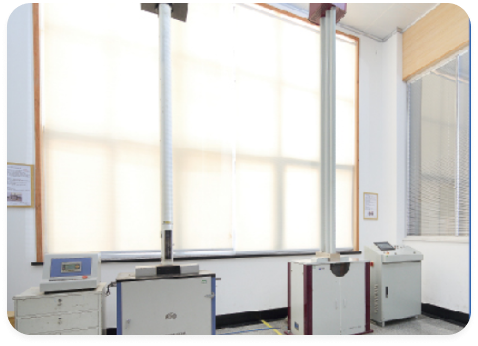

Our Facilities

-

Certifications

-

Projects

-

Technical Supports