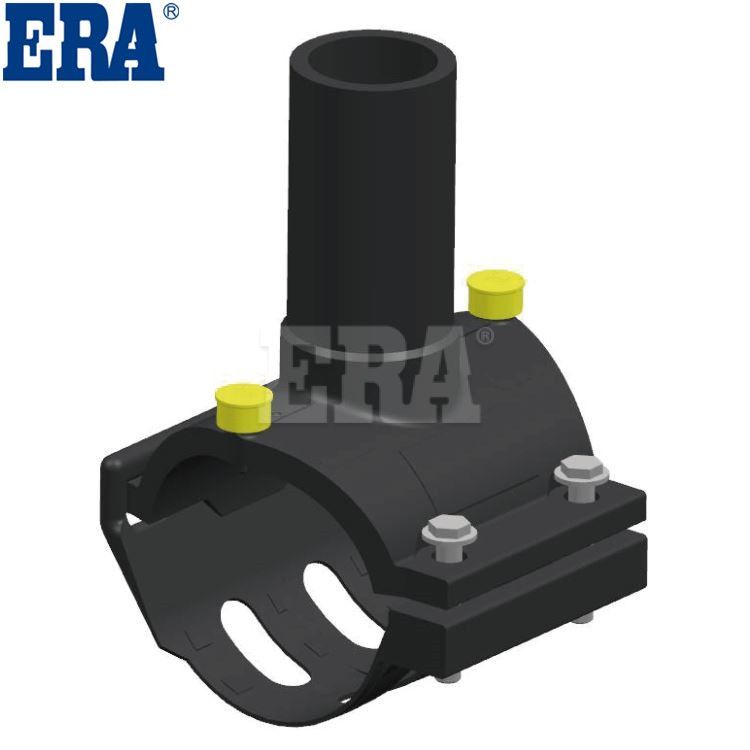

ERA Electrofusion Joints: Advanced Electric Fusion Pipe Fittings for Reliable Connections

Electric Fusion Pipe Fittings from ERA are engineered to create seamless, durable connections using heat-generated energy, ensuring fast and dependable joint integrity. These state-of-the-art fittings, along with expertly fused Electrofusion Joints, guarantee a leak-proof, long-lasting bond between plastic pipes and fittings.

Utilizing cutting-edge technology, Electric Fusion Pipe Fittings leverage the power of electric current to melt and fuse materials. This process produces Electrofusion Joints that exhibit strength equivalent to that of the pipe itself, effectively preventing leaks and chemical corrosion. The design ensures that the connections are both consistent and reliable, significantly reducing maintenance costs and extending the overall service life of the pipeline system.

Advantages of ERA Electric Fusion Pipe Fittings

Strong Joints: The fusion process creates Electrofusion Joints that are as robust as the pipes, ensuring a unified, leak-free connection.

Durability: With exceptional resistance to chemicals, temperature fluctuations, and wear, Electric Fusion Pipe Fittings maintain structural integrity for longer periods compared to mechanical joints.

Cost-Effectiveness: The efficient, maintenance-free design of Electric Fusion Pipe Fittings minimizes future repair costs while offering a lower initial investment than traditional mechanical connections.

Easy Installation: The streamlined electric fusion process simplifies the joining of pipes, allowing skilled labor to complete multiple joints in a single day, thereby reducing installation time and labor expenses.

How to Choose Electric Fusion Pipe Fittings

Selecting the right Electric Fusion Pipe Fittings involves several key considerations:

Material Compatibility: Ensure that the fusion fittings are certified and compatible with the existing pipe materials (e.g., PE, PVC).

Physical and Chemical Properties: Evaluate the fittings' resistance to temperature extremes, chemical exposure, and environmental factors to maintain joint integrity.

Size Matching: Verify that the dimensions of the fittings perfectly align with the pipes to avoid gaps or improper seals.

Pressure Rating: Choose fittings that exceed the design working pressure of your pipeline system for added safety and reliability.

Application Requirements: Consider the specific demands of your installation—whether for water supply, gas transportation, or industrial chemical handling—to select the most appropriate Electric Fusion Pipe Fittings.

Installation Guidelines for Electric Fusion Pipe Fittings

Successful installation of Electric Fusion Pipe Fittings is critical to achieving robust Electrofusion Joints:

Before Welding:

Confirm that all fittings meet the specified diameter and material standards.

Clean and prepare pipe surfaces to remove contaminants like sand, water, or oil, ensuring optimal fusion quality.

Calibrate the welding equipment to deliver the precise voltage and amperage required.

During Welding:

Monitor the temperature closely to avoid underheating or excessive melting, ensuring the formation of perfect Electrofusion Joints.

Follow detailed assembly guidelines for proper alignment and secure fixation until the welding process is complete.

After Welding:

Allow the joints to cool undisturbed for natural solidification.

Perform pressure and leakage tests to verify the integrity of each Electric Fusion Pipe Fittings installation before proceeding with additional work.

ERA electrofusion fittings are a revolutionary solution for manufacturing highly integrated electrofusion fittings that are strong, durable and cost-effective. Trust the superior performance of ERA electrofusion fittings for all of your plumbing needs and its unmatched reliability.